PT-C Series

EasyClean Design

BENEFITS

Results are convincing

– Simple, robust design for easy use and long life

– Available with single or double mechanical seal systems for pressure or vacuum applications

– Sterile double mechanical systems available food or pharmaceutical processing

– Capable of operating under pressures of up to 10 bar

– All parts in contact with the product are made from 316L Stainless Steel

– Generators can be made from special metals such as Hastelloy for use with abrasive materials or coated to minimize attack by corrosive chemicals

– Special surface finishes available for food and pharmaceutical applications

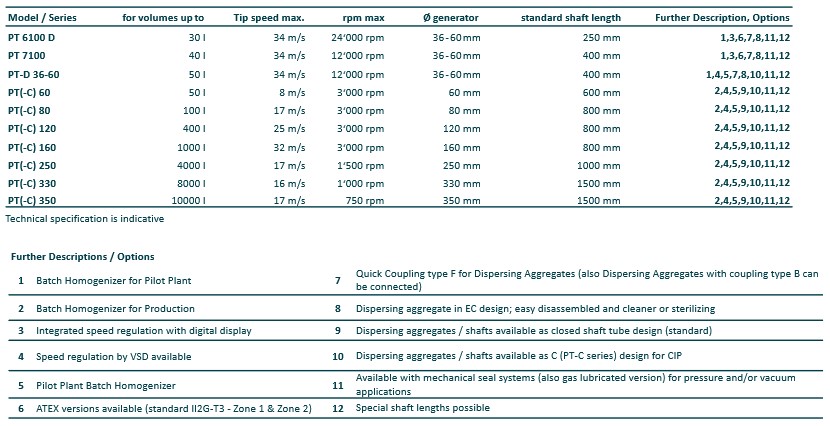

– POLYTRON® come in various sizes for batch volumes from 50 to 10 000 liters

– Shaft lengths can be customized for any particular application

– Rotor/Stator can be provided with specially designed injectors for introducing solids or liquids directly into the homogenization zone

– Available as CIP (Clean In Place) or CR (Clean Room) compatible machines

– Explosion-proof versions according to ATEX and NEMA are available for XP applications

– POLYTRON® can be mounted on stationary or moveable stands. In addition, the stands can be offered as manual lift or with the heavier motors, we recommend an electric lift

TECHNICAL INFORMATION

-

400

-

25

-

120 / 800 (Standard)

-

up to 5.5kW

-

3000 rpm (max.)