Efficient Emulsification

Application purpose

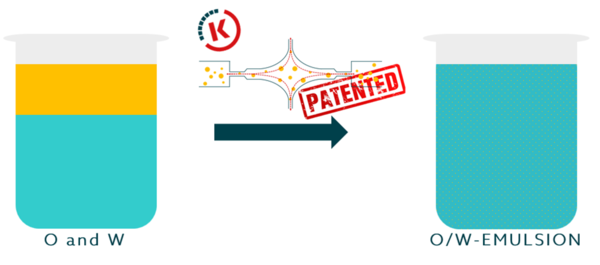

To efficiently emulsify formulations with high viscous ratios using the novel high-pressure unit ATOMIX®.

Challenges

High viscous ratios i.e., viscosity of the dispersed phased (Ƞd) / viscosity of the emulsion (Ƞe) is difficult to emulsify.

How did we achieve it?

When designing an emulsification process, the bulk and interfacial rheology of the target formulation should be considered. For example, formulations with high viscosity ratios are particularly challenging to emulsify by conventional methods since those consume significant energy and the control over polydispersity is limited.1 To overcome this issue, when the formulation requires a high viscous dispersed phase, innovative technologies should be implemented.

The passion for innovation is one of Kinematica’ s signatures and it is applied not only to its well-known rotor-stator systems but also to new technologies. That’s how in collaboration with ETH Zürich, the novel ATOMIX® was developed with a new design of the working chamber.

The Kinematica Solution

How can ATOMIX® ensure smaller droplet sizes even at high viscous ratios? The working chamber is specially designed to have a large amount of elongational flow, which is critical to achieve efficient droplet breakup.

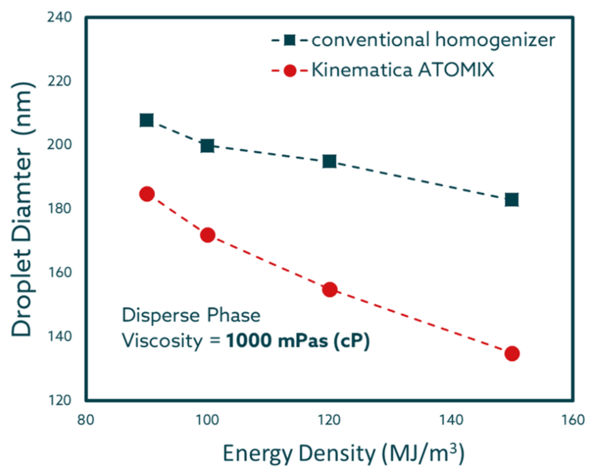

A droplet breakup only happens when critical stress is exceeded. Three mechanisms of disruption can be distinguished: shear forces in laminar flow, shear forces in turbulent flow and inertial forces (like local pressure fluctuations) in turbulent flow. It is typical that disruption in turbulent flow becomes more difficult as viscosity of the dispersed phase increases. Considering this, the droplet size at constant energy density increases as the viscosity of the disperse phase rises.2

The combination of high pressure and an ideal working chamber design allows for 30% smaller droplets compared to our competitors.

Due to its special and re-engineered design of the working chamber, in ATOMIX® the droplets are mainly disrupted due to elongational forces overcoming the issue that supposed the disruption in turbulent flow. This is translated in up to 30% smaller droplets even at high viscous rates!

Do you want to have more information? Contact us here or send an email to science@kinematica.ch.

1 Hofmann, M., Bayles, A. V., & Vermant, J. (2021). Stretch, fold, and break: Intensification of emulsification of high viscosity ratio systems by fractal mixers. AIChE Journal, 67(5). https://doi.org/10.1002/aic.17192

2 Stang, M., Schuchmann, H., & Schubert, H. (2001). Emulsification in High-Pressure Homogenizers. Engineering in Life Sciences, 1(4), 151. https://doi.org/10.1002/1618-2863(200110)1:4<151::AID-ELSC151>3.0.CO;2-D