Recovery

APPLICATION PURPOSE

To understand product losses in continuous operation in MEGATRON ® line.

CHALLENGES

- Pilot plant operations

- Process stability

- Material dependency

HOW DID WE ACHIEVE IT?

One of the biggest challenges that all industries are facing nowadays is improving the product quality and increasing operational safety while reducing costs and achieving a sustainable process. To accomplish such a challenge, reduction of product losses is an important task 1 that is aligned with the Sustainable Development Goal (SDG) 12 (Responsible consumption and production) by contributing with the reduction on waste generation 2.

Product loss can occur due to unpredictable production stops, problems during intermediate tank storage and planning decisions, but also due to equipment design and piping length. It is at this point where Kinematica’s state-of-the-art technology can contribute 3.

THE KINEMATICA SOLUTION

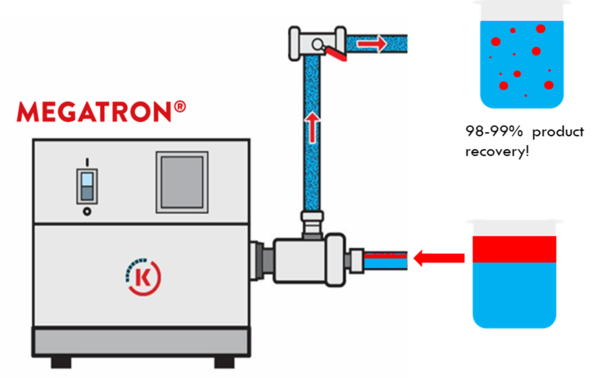

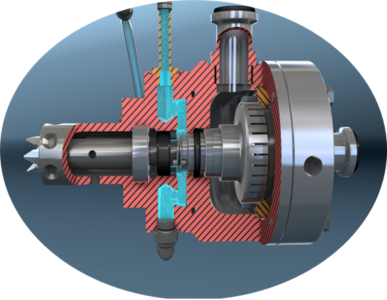

MEGATRON® line is Kinematica’s solution to ensure not only an efficient process with smaller particle / droplet sizes in inline processes, but also product recovery up to 99% due to the compact design of the working chambers that allows complete discharge!

Would you like more information? Contact us here or send an email to science@kinematica.ch.

1 Akkerman, R., & van Donk, D. P. (2008). Development and application of a decision support tool for reduction of product losses in the food-processing industry. Journal of Cleaner Production, 16(3), 335–342.

2 Sustainable development goals: United Nations Development Programme. UNDP. (n.d.). Retrieved March 10, 2022, from https://www.undp.org/sustainable-development-goals

3 Böe, K., & Worczinski, G. (2005). A New Piping System for Process Plants. Master Brewers Association of the Americas, 42(2), 133–139